Why Choose Flexible Packaging?

Deciding the right packaging for your product is not a simple task. This task can seem overwhelming for consumer packaged goods, manufacturers, and contract packagers. It can feel like a bunch of options are thrown at you, and you don’t even know where to begin.

Flexible packaging film is a great option for many product packaging needs.

Flexible packaging film is a great option for many product packaging needs.

Flexible packaging is one of the fastest growing packaging types and is more sustainable than other packaging options. Products that are made with flexible packaging have not only made a difference with product waste, but also in the lives of consumers.

Table of Contents:

- What is Flexible Packaging?

- Why Flexible Packaging is Important?

- What You Should Know About Flexible Packaging

- How to Choose the Right Packaging Type

- Flexible Packaging vs Rigid Packaging

- Final Recap

- Frequently Asked Questions

What is Flexible Packaging?

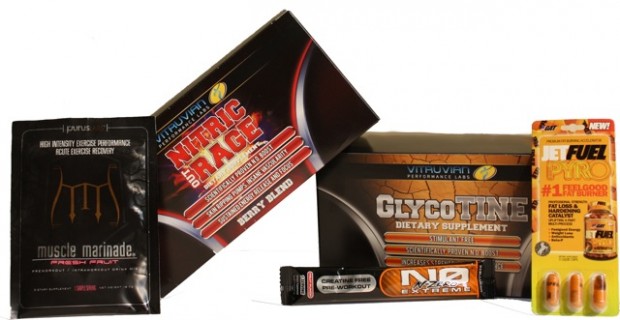

Flexible Packaging is a type of product packaging that can be shaped and changed. It can be reused, easily opened, resealed, and is lightweight and more cost-efficient. It requires less energy and fossil fuels to manufacture flexible product packaging, making it more sustainable than other types of packaging materials. Examples of flexible packaging include bags, pouches, shrink films, tubes, sleeves, and carded packaging.

Why Flexible Packaging is Important?

There are many benefits of using flexible packaging materials for your product packaging compared to other types of packaging materials.

There are many benefits of using flexible packaging materials for your product packaging compared to other types of packaging materials.

Benefits include:

- Extended product shelf life

- Lightweight

- Cost-efficiency

- Lower shipping costs

- Minimal material used

- Less consumer waste

Utilizing flexible packaging lessens our carbon footprint. Because products, especially food, can be resealed, the shelf life is extended and less waste is produced. Compared to other types of packaging materials, flexible packaging is more environmentally friendly.

What You Should Know About Flexible Packaging

A reverse-print method is used for flexible packaging. The product packaging design is printed between laminated materials, protecting the ink. Products, especially food, are protected from the ink. Other types of printing on flexible packaging include flexography, digital printing, rotogravure, and lithography.

How to Choose the Right Packaging Type

When determining which packaging type is best for your product, there are some things to take into consideration. Follow these steps to find which packaging material you should use.

- Product type – Think about what type of product you want to package.

- Packaging Dimensions – Consider the size, weight, and shape of your product. Note any specifics that need to be accounted for when packaging.

- How Much Is Flex Packaging? – What is your budget for packaging? Rigid packaging tends to be more expensive, while flexible packaging is more cost-efficient.

- Envision your packaging – Decide how you want your product packaged in both flexible film and rigid packaging options. There are many types of both packaging materials. Would your product fit best in a pouch, can, box, bag, etc.?

- Compare packaging – Ask yourself which packaging type your design would look best on and function most efficiently.

- Shipping – Consider how your product will be shipped and how many people will handle it.

- Find a pro – Contact a packaging specialist at PSI.

The best way to select the appropriate packaging material for your product is to contact a professional. They are there for that reason. They can guide you through the process and help you envision the final packaging better.

Flexible Packaging vs Rigid Packaging

Flexible Packaging:

- Uses less material

- Can be shaped and changed

- Lightweight

- Durable, can return back to original shape

- Reusable

- Resealable

- Sustainable

- Customizable

Examples of flexible packaging include bags, sleeves, tubes, and pouches.

Rigid Packaging:

- Uses more material

- Cannot be shaped and changed easily

- Heavier

- Less durable, can dent and break

- Protective against outside environment

- Costs more to customize

- Easier to store

Examples of rigid packaging include cans, plastic boxes, glass containers, and cardboard.

Final Recap

When looking at types of packaging materials, it is worth noting that flexible packaging and flexible film have increased in popularity over the past few years. One major reason this has happened is because of its higher sustainability compared to rigid packaging. Less consumer waste is produced by flexible packaging because of extended shelf lifes and smaller amounts of packaging material used.

To find out if your product should be packaged in flexible packaging film, contact a specialist. PSI is a flexible packaging manufacturer and can help with your product packaging supply needs. PSI also offers custom product packaging for flexible packaging and flexible film materials.

Frequently Asked Questions

Got questions? We’ve got answers.

What are examples of flexible packaging?

Products that are packaged in flexible packaging and flexible film include:

- Bags – Paper, non-woven, plastic, courier, and biodegradable

- Adhesive tapes

- Bubble wrap and air bubble pouches

- Foam

- Films

- Foil

- Corrugated roll

- Pouches

What are the advantages vs disadvantages of flexible packaging?

Advantages

- Extended shelf life of products

- More sustainable than other packaging options

- Lightweight

- Cost-efficient

- Durable and can be reshaped and reformed

Disadvantages

- Technological changes and innovation struggles

- It’s more sustainable but still not great for the environment

- Less protective

- Not as easy to store

- Requires highly skilled employees to operate machinery

Is flexible packaging sustainable?

The Flexible Packaging Association has supported sustainability efforts through use of flexible packaging. Flexible packaging manufacturing uses less fossil fuels and water and emits less greenhouse gases. More products packaged in flexible packaging materials can be transported at once, lowering shipping and transportation emissions. Flexible packaging extends the shelf life of many products, reducing the amount of food waste with perishable products.

Overall, flexible packaging is more sustainable than rigid packaging. While it is not completely eco-friendly yet, using flexible packaging materials such as bio-polymers and plant-based plastics are a big step in that direction.

What is flexible packaging made out of?

Flexible packaging can be made out of any of the following materials:

- Polyester

- High Density Polythene / polyethylene (HDPE)

- Low Density Polythene / polyethylene (LDPE)

- Polyethylene Terephthalate (PET, PETE)

- Polypropylene (PP)

- Polyolefin (POF)

- Polyvinyl Chloride (PVC, Vinyl)

- Paper

- Metalized film

- Release-coated films

- Anti-static films

- Conductive films

- Nylon films

- Cellophane

- PLA (polylactic acid)

- Biodegradable PE

- Biodegradable laminations

- Multi-layer adhesive laminations

What are different types of packaging materials?

Packaging materials can be divided into two categories: flexible and rigid. Flexible packaging can be shaped and changed and does not dent or deform easily. Rigid packaging is known for being protective, but heavier. Both flexible and rigid packaging can be coupled with protective packaging, like styrofoam and bubble wrap.

Printed boxes and packaging

Printed boxes and packaging